PDR (Paintless Dent Repair) is a cost-effective and efficient method for repairing dents in automotive aluminum body panels, preserving structural integrity and original factory finishes. Preferred by both professionals and DIY enthusiasts, this non-invasive technique avoids extensive sanding or repainting, saving time and reducing environmental impact, while effectively addressing minor dents, scratches, and bumps on aluminum-bodied vehicles.

Discover the transformative power of PDR (Paint Damage Repair) on aluminum panels. This innovative technique offers a fast and cost-effective solution for various aluminum repairs, from minor dents to significant damage. In this comprehensive guide, we’ll explore the benefits of PDR, walk you through the step-by-step process, and uncover the key factors that determine the time it takes to restore your aluminum panels to their original condition.

- Understanding PDR for Aluminum Panels

- – What is PDR and its application on aluminum panels?

- – Benefits of PDR technique for aluminum repairs

Understanding PDR for Aluminum Panels

PDR for aluminum panels refers to the process of Plastic Deformation Repair, specifically tailored for automotive aluminum body panels. This technique is a game-changer in the auto industry, offering a cost-effective and efficient solution for repairing dents and dings on aluminum cars. Unlike traditional painting or replacing damaged panels, PDR gently manipulates the metal back into its original shape without leaving visible repair marks.

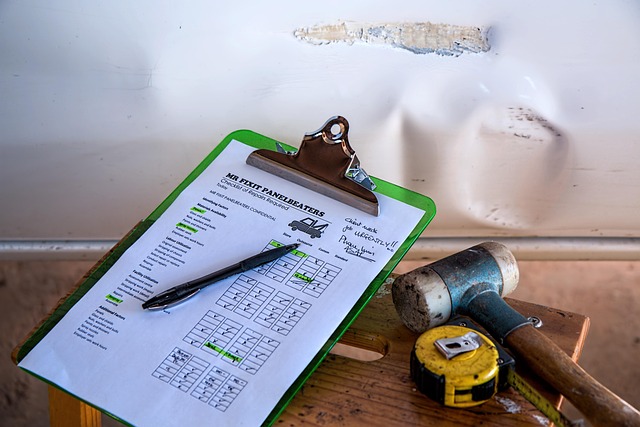

The process involves several steps: inspection to assess damage, clamping the panel securely, and then using specialized tools to apply pressure while a trained technician guides the metal back to its original form. This method is not only faster and more affordable than complete car paint services or auto maintenance for aluminum panels but also ensures the vehicle’s structural integrity remains intact. It’s a popular choice among both professional car repair services and DIY enthusiasts looking to restore their aluminum-bodied vehicles to near-perfect conditions.

– What is PDR and its application on aluminum panels?

PDR, or Paintless Damage Repair, is a specialized technique used to restore and fix dented or damaged automotive surfaces without the need for traditional painting methods. This non-invasive approach has gained significant popularity in the automotive industry, including its application on aluminum panels. When it comes to PDR for aluminum panels, this advanced technique offers an efficient and cost-effective solution for various types of dents, scratches, and minor impact damage.

Aluminum, known for its lightweight and corrosion-resistant properties, is commonly used in modern vehicle construction, especially in the body panels of cars and trucks. Traditional repair methods often involve extensive sanding, priming, and repainting, which can be time-consuming and costly. PDR provides an alternative by allowing skilled technicians to massage and shape the metal back to its original form, effectively removing dents and restoring the panel’s aesthetics. This process not only saves on labor costs but also reduces the environmental impact associated with discarding damaged panels and repainting. It is a preferred method in collision repair centers and car paint services for its ability to preserve the original factory finish and ensure a seamless repair that matches the vehicle’s overall appearance.

– Benefits of PDR technique for aluminum repairs

The Positive Impact of PDR on Aluminum Repairs

When it comes to repairing aluminum panels, particularly in the automotive industry, PDR (Paintless Dent Repair) stands out as an innovative and highly effective technique. This method offers numerous advantages over traditional auto painting and bumper repair methods. One of its key benefits is speed; PDR can restore damaged aluminum panels to their original condition without the need for extensive sanding or repainting. This not only saves time but also minimizes costs, making it a cost-efficient solution for both car owners and repair shops.

Additionally, PDR is environmentally friendly. By eliminating the use of additional paints and solvents, this technique reduces the carbon footprint associated with auto painting processes. The precision required in PDR ensures that the original finish and texture of the aluminum are preserved, making it an ideal choice for maintaining the vehicle’s overall aesthetics. This method is especially valuable for repairing minor dents, scratches, and bumps, ensuring your car looks as good as new without the need for extensive body work.

PDR (Paintless Dent Repair) for aluminum panels offers a highly effective and efficient solution for cosmetic dent repair. By leveraging specialized techniques and tools, this non-invasive method preserves the original finish while significantly reducing repair time and costs compared to traditional methods. The benefits of PDR are numerous, from maintaining the panel’s aesthetic value to ensuring structural integrity without the need for extensive painting or replacement. For aluminum panel repairs, PDR stands out as a reliable and eco-friendly choice, making it an excellent option for both professional bodyshops and DIY enthusiasts.